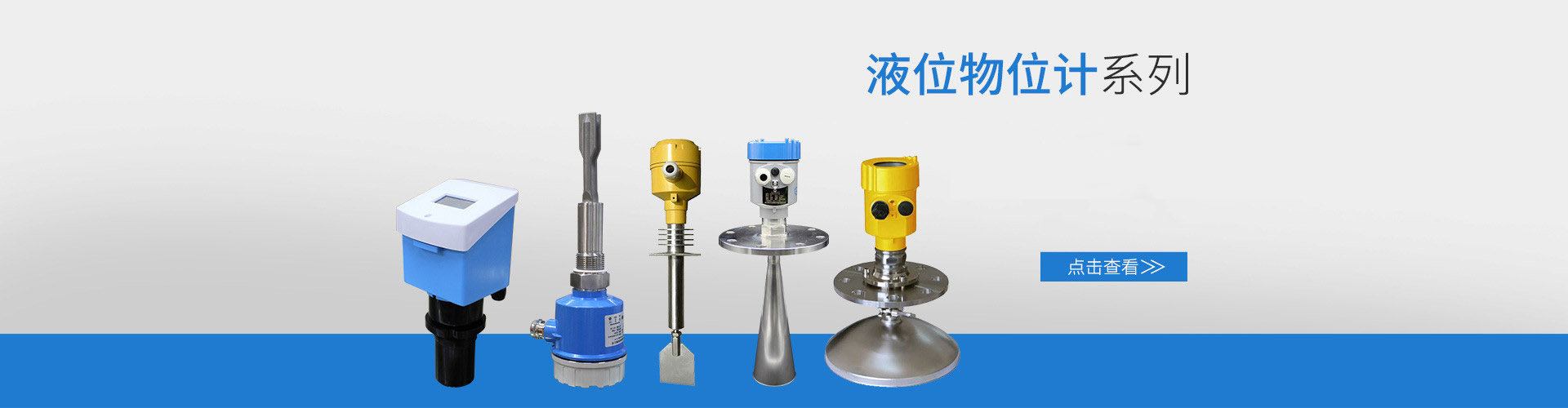

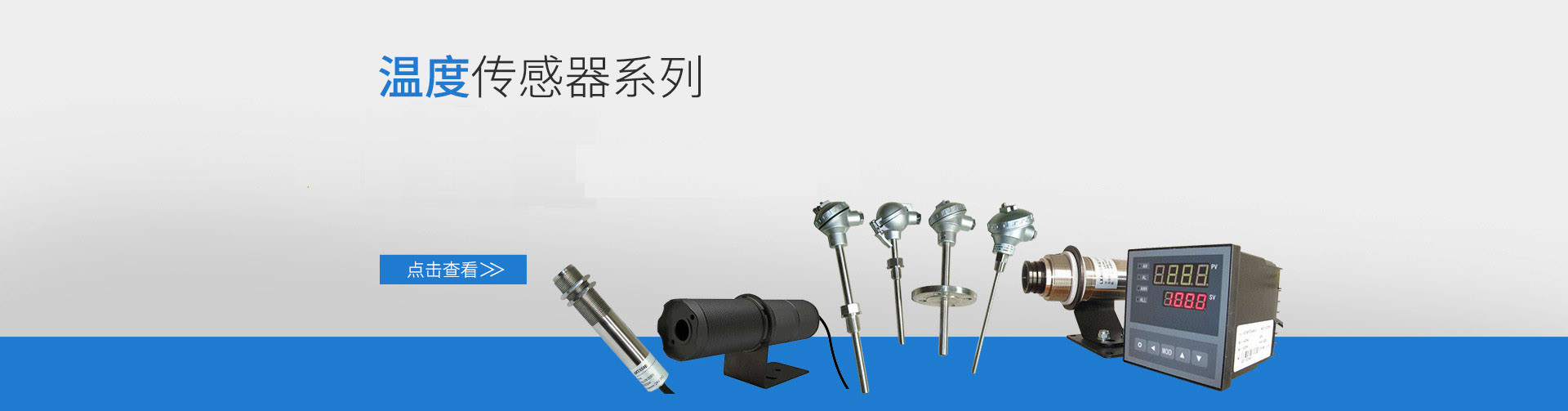

一提到液位计,大家可能都比较熟悉,它通常被应用于检测液体的容量、深度和水位高度。液位计作为一种测量仪器,在各种场景下都十分实用,比如汽车的油量测量就离不开它。但是,你知道吗?有一种情况是液位计“力不从心”的,那就是水管中的液体泄漏。这种情况下,液位计可能就“检测不出来”了。为什么会这样?我们又该怎么办?今天就让我们一起来扒一扒这背后的奥秘。 我们先来了解一下液位计的工作原理。液位计通常通过对液体的压力、高度或液面平面的测量,来实现对液位的*检测。常见的液位计有浮球液位计、超声波液位计、雷达液位计、微波液位计等。以浮球液位计为例,它通过浮球上磁浮子的上下移动,驱动磁致伸缩传感器,将液位的变化实时转化为电信号,实现对液位的*测量。看似简单,但实际应用中,它有几个关键因素会影响测量效果:

液体的粘度:粘度较大的液体,会导致浮球移动速度变慢,从而延迟液位变化信息的传导。

液体的透明度:如果液体不够透明,会影响光线通过液体,从而影响到光电液位计的测量准确度。

液体的气泡和杂质:气泡和杂质会干扰液位计的正常工作,导致测量结果不准确。

液体的流动状况:液体若有较大流速或 turbulence( turbulence 指流体中高速的、乱流的运动),会造成液位计的振动,从而影响测量。

以上这些因素,会导致液位计的测量结果出现偏差,在一定程度上,甚至可能“检测不出”液体的变化。特别是对于静态水管中的液位变化,由于水管中液体一般无流速,如果发生泄漏,液位的下降会十分缓慢,而这些变化就可能被液位计“忽略”。 那么,如何解决这个问题? 针对液位计的“盲区”,我们可以采取以下几措施:

定期检修维护:定期对液位计进行检查、清洁和校准,确保其感应器、传感器等部件处于良好状态,保持测量精度。

选择合适的液位计:不同类型的液位计,适用场景不同。例如,可以选择 suitable for water supply 的专用液位计,或采用多点液位检测方式,提高检测精度。

结合其他检测手段:在液位计基础上,增加辅助的漏液检测设备,如可检测管道内部情况的声波检测仪,或在管道外使用热像仪,发现管道漏液产生的温度差异。

定期巡查:在液位计“失灵”的情况下,可通过定期人工巡查,发现异常液位变化。同时,可通过计量水管流入和流出的水量,判断是否有漏水情况。

升级液位监测系统:使用*的液位监测系统,如基于物联网的智能液位监测系统,实时、准确地监测液位变化,并可将数据远程传送到管理平台,*时间发现异常。

在了解了这些方法后,我们不难发现,虽然液位计有其限制,但其实完全可以“有备无患”。通过辅助设备、智能化升级等方式,可以有效避免液位计“检测不出来”的情况。当然,除了上述办法,还有许多巧妙的解决方案。例如,一些智能液位计可以实现漏液的实时监测和预警,通过 AI 算法分析液位变化趋势,*时间通知用户;又或是在水管外使用特殊涂层,可视化漏液位置等。 Liquid level detection is a crucial aspect of maintaining efficient operations across various industries. However, there are situations where even the most sophisticated liquid level gauges cannot detect leaks in pipes, leading to potential challenges. Understanding the intricacies of these circumstances and their solutions is vital for ensuring reliable liquid level monitoring. Liquid level gauges rely on specific principles to function accurately, such as pressure measurement, optical detection, or magnetic floatation. But, several critical factors can impact their performance, including liquid viscosity, transparency, impurities, and flow rate. These factors can cause delays or distortions in the measurement, making slow leaks in static pipes hard to detect. To tackle this issue, regular maintenance and calibration of the gauges are essential. This includes timely cleaning, sensor checks, and adjustments to ensure the device's accuracy. Choosing the right type of liquid level gauge for the specific application is also crucial. Some gauges are better suited for water supply pipes, while others might be more accurate for detecting static liquid levels. Additionally, we can augment liquid level gauges with complementary leak detection technologies, such as ultrasonic or thermal imaging devices, which can provide more comprehensive coverage. Leaks can also be detected by conducting periodic physical inspections and comparing the levels of inflow and outflow. For more robust solutions, upgrading to advanced liquid level monitoring systems can be beneficial. These systems often employ IoT capabilities, providing real-time data and alerts, enabling remote monitoring and immediate action. Furthermore, enhancements like AI-powered analysis and specialized coatings for pipes can also be considered. With these strategies, you can ensure that your liquid level detection needs are met, even in scenarios where traditional gauges fall short. Stay ahead of leaks and maintain optimal efficiency in your operations! 希望这篇文章能帮助你更好地了解液位计的应用和注意事项,如果你也有遇到的类似问题,不妨参考以上方法,或寻求*人士的意见,确保问题及时解决。