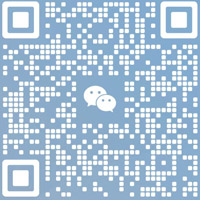

A Comprehensive Review of Level Measurement Instruments: A Deep Dive into Product Selection and Application

Accurate and reliable level measurement is critical across numerous industries, from process manufacturing and water management to the pharmaceutical and petroleum sectors. The selection of the appropriate level measurement instrument is therefore paramount, demanding a thorough understanding of its capabilities, limitations, and suitability for specific applications. This review delves into the diverse landscape of level measurement instruments, examining their core principles, performance characteristics, and application-specific considerations.

I. Core Principles and Technologies:

Level measurement instruments employ a variety of physical principles to determine the level of a substance within a container or vessel. These principles can be broadly categorized into:

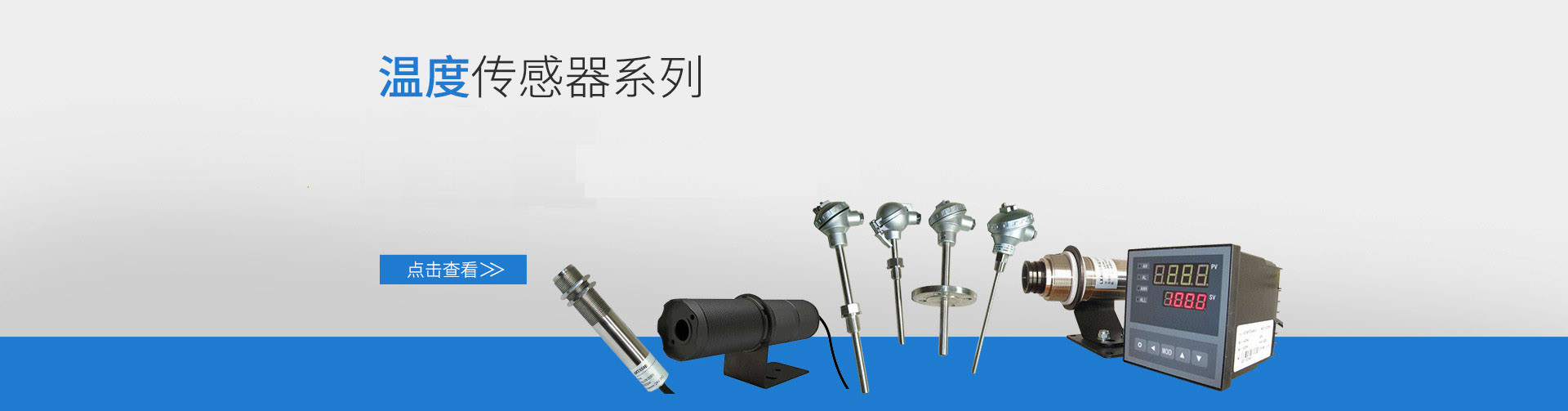

Hydrostatic Pressure Measurement: This method utilizes the relationship between fluid height and hydrostatic pressure. Pressure sensors, often diaphragm-based or capacitive, are positioned at the base of the vessel, measuring the pressure exerted by the liquid column. This approach is particularly suitable for liquids with known densities.

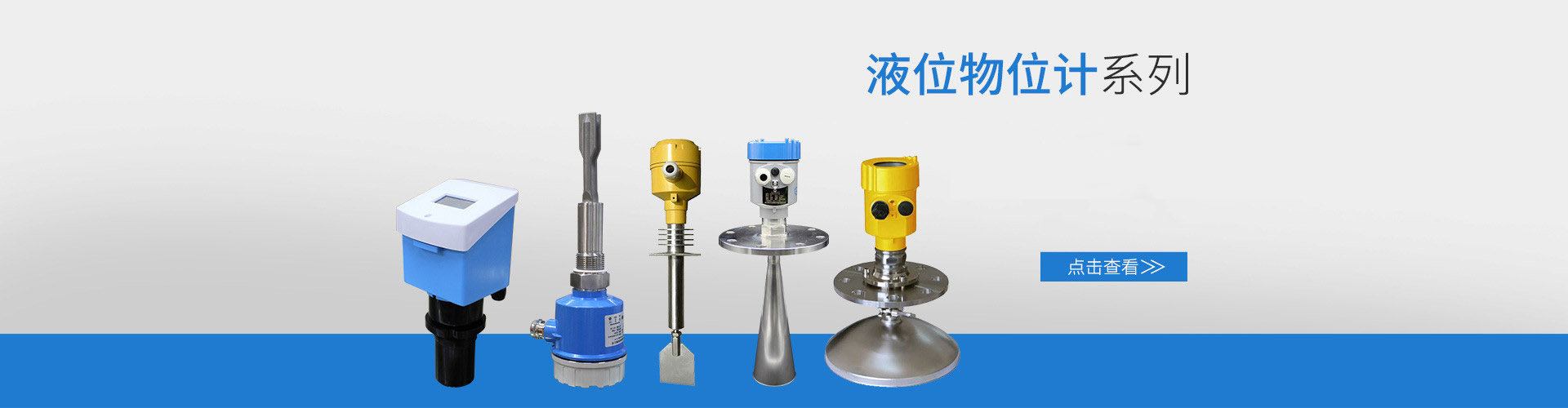

Ultrasonic Measurement: Ultrasonic level sensors emit ultrasonic waves that bounce off the liquid surface. By measuring the time-of-flight of the waves, the distance to the surface, and therefore the liquid level, is determined. This non-contact method is advantageous for applications involving corrosive or high-temperature liquids. However, factors such as foam, vapor, or dust can affect accuracy.

Radar Measurement: Similar to ultrasonic measurement, radar level sensors employ electromagnetic waves to determine the level. Radar technology offers superior performance in challenging environments with significant vapor or dust, as electromagnetic waves are less susceptible to interference compared to ultrasonic waves. Different frequency ranges (e.g., guided wave radar, free space radar) are available to suit various applications and vessel characteristics.

Capacitance Measurement: Capacitive level sensors measure the change in capacitance between a probe and the vessel wall. The capacitance varies directly with the dielectric constant of the material and the level of the liquid. This method is suitable for liquids with a high dielectric constant, but can be affected by changes in temperature and the properties of the vessel material.

Float and Displacer Systems: These mechanical systems utilize a float or displacer that rises and falls with the liquid level. The float's movement is mechanically linked to an indicator or a transmitter, providing a direct reading of the level. While robust and reliable, these systems are typically limited to applications requiring simpler level detection and may be unsuitable for high-pressure or high-temperature environments.

II. Product Parameters and Specifications:

Selecting the appropriate level measurement instrument requires careful consideration of several key parameters:

Measurement Range: The minimum and maximum level that the instrument can accurately measure. This parameter should be chosen to encompass the expected operating range with sufficient margin.

Accuracy: The degree of deviation between the measured level and the actual level. Accuracy specifications are typically expressed as a percentage of the full scale or an absolute value.

Repeatability: The consistency of repeated measurements under identical conditions. High repeatability indicates the reliability of the instrument's readings.

Response Time: The time it takes for the instrument to respond to changes in liquid level. Fast response times are crucial for applications requiring quick and precise level control.

Process Connections: The type of connection required for integration with the process piping and instrumentation. Common connection types include threaded, flanged, and clamp connections.

Material Compatibility: The compatibility of the instrument's materials with the process fluid. Materials should be selected to resist corrosion, erosion, and chemical degradation.

Operating Temperature and Pressure: The instrument's ability to function reliably under specified temperature and pressure conditions.

III. User Experience and Maintenance Considerations:

The ease of installation, configuration, and maintenance plays a significant role in the overall user experience. Ideally, instruments should feature user-friendly interfaces, self-diagnostic capabilities, and minimal maintenance requirements. Regular calibration and preventative maintenance are crucial for ensuring the long-term accuracy and reliability of the instrument. Proper installation, avoiding potential interference from external factors, is also essential for optimal performance.

IV. Advantages and Limitations of Different Technologies:

Each level measurement technology offers unique advantages and limitations:

Technology Advantages Limitations Hydrostatic Pressure Simple, cost-effective, reliable for known densities Sensitive to density changes, not suitable for all liquids Ultrasonic Non-contact, versatile Affected by foam, vapor, and dust Radar Superior performance in challenging environments More expensive than some other technologies Capacitance Suitable for high dielectric constant liquids Affected by temperature and vessel material Float & Displacer Robust, simple Limited range, unsuitable for high pressure/tempV. Target User Groups and Applications:

Level measurement instruments find application across a diverse range of industries and processes. Target users include:

Process Engineers: Responsible for designing, optimizing, and monitoring industrial processes. Instrumentation Technicians: Involved in the installation, calibration, and maintenance of level measurement systems. Plant Operators: Responsible for monitoring and controlling process parameters, including liquid levels. Quality Control Personnel: Ensuring the consistency and quality of products through precise level measurement.Specific applications include:

Water and Wastewater Treatment: Monitoring water levels in reservoirs, tanks, and treatment plants. Chemical Processing: Controlling liquid levels in reactors, storage tanks, and blending vessels. Food and Beverage Processing: Monitoring levels in tanks, silos, and processing lines. Pharmaceutical Manufacturing: Ensuring precise level control in sterile environments. Oil and Gas: Monitoring levels in storage tanks, pipelines, and production facilities.VI. Conclusion:

Selecting the appropriate level measurement instrument requires a thorough understanding of the specific application requirements and the capabilities of each technology. This review has provided an overview of the common technologies, their parameters, and their suitability for various applications. By carefully considering the factors discussed, users can select the optimal instrument to ensure accurate, reliable, and efficient level measurement within their specific processes. Continuous advancements in sensor technology are driving improvements in accuracy, reliability, and ease of use, further expanding the applications of level measurement in diverse industries.